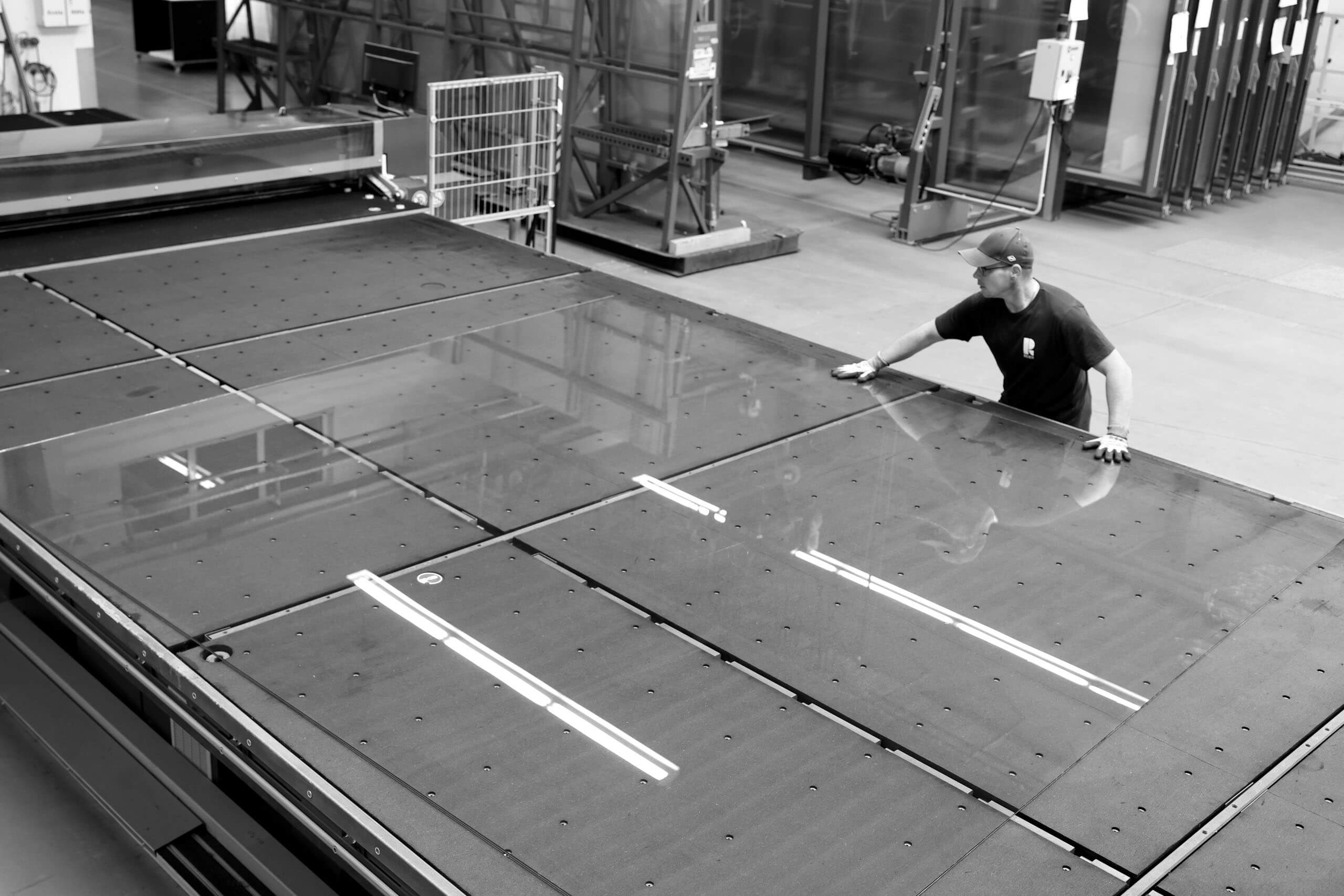

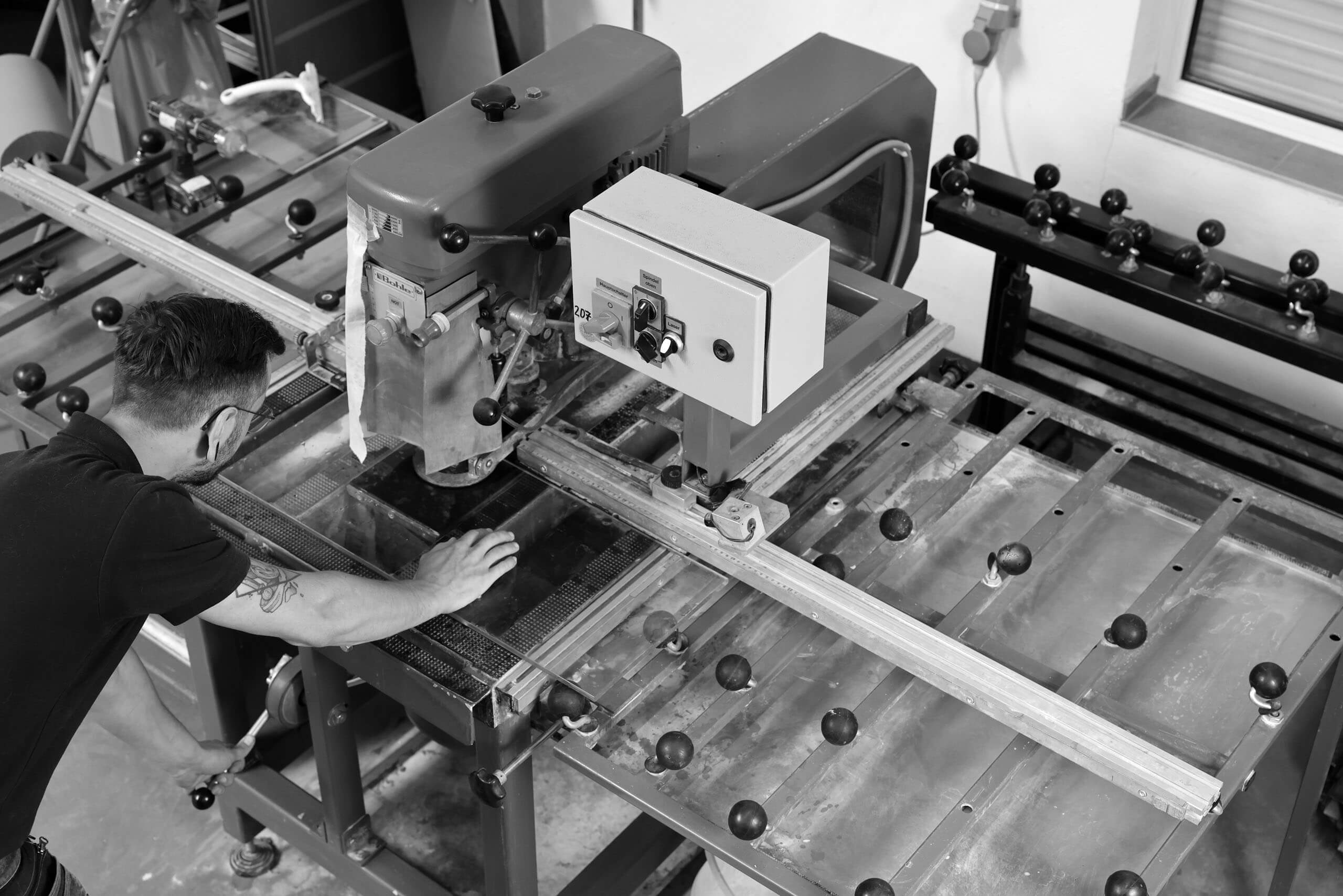

The glass workshop is primarily responsible for cutting laminated safety glass and float glass to the needed dimensions and forms. This is done by CNC-controlled devices. Afterwards, the glass edges are finely ground and polished.

The devices can process optic white or non-reflective glass panels up to 6,00 x 3,21 meters. Moreover, glass panels of different sizes and safety standards, up to bullet-resistant glass, may be used.

Additionally, glass panels are coated according to RAL, NCS or other requirements to partially conceal structural display case components.